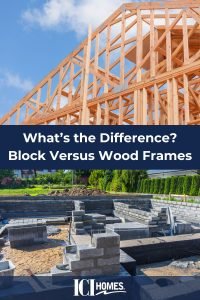

We at ICI Homes have built new custom Florida homes all over the state for more than four decades, and one frequent question our sales associates, floor plan designers and builders hear from customers is a good one: what’s the difference between a block or wood-framed home?

Let’s peel back the layers of a new custom Florida home to discover what’s under its attractive elevation — and why that matters.

Let’s peel back the layers of a new custom Florida home to discover what’s under its attractive elevation — and why that matters.

In residential construction, elevation refers to a home’s exterior appearance. Inside the elevation of your new custom Florida home are its stout bones. Think of a home’s frame as its skeleton. Just like our skeletons, a home’s bones should be strong, secure and long-lasting.

To accomplish that, your new custom Florida home will be framed with either concrete block or engineered wood. And there are solid reasons for both construction techniques.

Read on to discover the difference between block versus wood frames.

Key takeaways

- All ICI Homes are built on moisture-treated concrete slabs—no basements here in Florida.

- Block framing uses concrete blocks reinforced with steel rebar, offering strong, weather-resistant exterior walls ideal for Florida’s climate.

- Wood framing uses pressure-treated engineered lumber, nailed and secured to form the structure, then finished with plywood sheathing.

- Both framing methods meet Florida’s strict building codes and are designed to stand up to storms and high winds.

- Every ICI Home, whether block or wood framed, includes energy-efficient systems, smart home tech, and is built to our exclusive EQ Factor standard.

Block frames

In Florida, each new custom home begins with a cured, moisture-treated concrete slab. Nope — no basements! And no matter whether its “skeleton” is concrete block or engineered wood, its framing begins on that concrete slab.

All new custom Florida homes (regardless of framing technique) are built according to rigorous state and local codes to ensure those homes remain secure during storms, excessive winds and other weather vagaries.

In concrete block framing, steel rebar pieces already have been anchored in place to the concrete slab when it was poured. If you see a fresh-poured slab, that’s what all those vertical steel posts are, that rim the slab’s edges.

Once framing is a go, concrete blocks are spread with mortar and built up in alternating, interlocking fashion into exterior walls. The rebar “sticks” are threaded through hollow spaces in the blocks and secured with additional mortar.

Large pre-cast concrete slabs top each wall, ready for wooden roof framing or the addition of a second level.

Wood frames

Lots of pressure-treated lumber, nails, and other tie-down hardware! Engineered wood framing begins with wood pieces anchored to the concrete pad. These form the base for all wood framing.

From there, vertical posts of engineered lumber are nailed in place, forming exterior walls that are topped, eventually, with wooden roof trusses and clad on the outside with plywood.

Both techniques are winners

No matter which “skeleton” your new custom Florida home may have, know that all of our homes are built to an additional standard — our EQ Factor standard.

We use the latest residential building techniques and materials, then stock each home with energy-efficient appliances and mechanical systems, and the latest residential digital technology. You get the smartest smart home and an environmentally friendly one built in an airtight manner.

Prefer a deeper dive into block versus wood framing? One of our most popular Florida Lifestyles blogs tackles the topic here.

Curious about which ICI Homes master-planned communities and those in which we’re preferred builders use block or wood framing? Talk to ICI Homes here.